What is PLC Program | The Core Systems

Programmable Logic Controllers, or PLCs, are industrial automation devices that are ruggedized computers. These controllers are equipped with the power to fully automate a production line, a specific procedure, or even machines.

PLC programming is necessary for designing and implementing processes in accordance with customer needs. An industrial real-time application’s specific PLC program is a set of textual or graphical instructions representing the logic used in that application. The PLC hardware of a particular manufacturer comes with a special PLC programming software that enables the entry and development of user application code, which can then be downloaded to the PLC hardware.

This software also guarantees the Human Machine Interface (HMI) as a graphical representation of variables. The PLC begins to run the program repeatedly as soon as it has downloaded it to it and has been set to Run mode.

Devices for PLC Programming

To enter, modify, and troubleshoot a PLC program, different kinds of programming devices are used. Mobile phones and PCs are included in this group of programming terminals. A proprietary device is connected to a PLC using a connecting cable in the handheld programming device method. This tool consists of a set of keys that enable the entry, editing, and duplication of code into the PLC. For the purpose of making the programmed instruction visible, these handheld devices have a small display. These handheld gadgets are small and easy to use, but they just have a few features.

The most popular way to program a PLC is with a Personal Computer (PC) and the manufacturer-supplied software. We can run the PLC program on this PC in both online and offline modes, as well as edit, monitor, diagnose, and troubleshoot the PLC program.

The most widely used PLC programming language types

- Ladder Diagram (LD)

- Function Block Diagram (FBD)

- Structured Text (ST)

- Sequential Function Charts (SFC)

- Instruction List (IL)

Ladder Diagram (LD)

Ladder Diagram was initially modeled after relay-logic, which used physical objects, like switches and mechanical relays, to control processes. With the exception of the physical devices that require an electrical signal to be activated, Ladder Diagram replaces everything using internal logic.

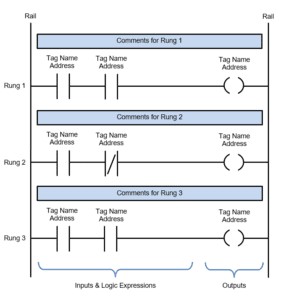

The ladder diagram, which represents the electrical connection on relay-logic schematics, is constructed as two vertical rails and two horizontal rungs.

All necessary input conditions, whether logical or physical, can be programmed to have an impact on output conditions.

Function Block Diagram (FBD)

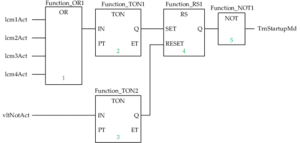

Another graphical language is the Function Block Diagram. Inputs and outputs are connected in blocks by connection lines in the function block diagram to represent a function.

To establish a system where you could set up many of the typical, repeatable tasks, such as counters, timers, PID Loops, etc., Function Blocks were initially developed.

Structured Text (ST)

The fourth programming language for PLCs is structured text. The foundation of this language is text.

High-level languages like “C,” “Basic,” and “Pascal” are similar to Structured Text.

It is an extremely powerful tool that can finish both tedious tasks that involve algorithms and arithmetic operations and repetitive ones.

Semicolons are used in the code to restrict statements, and these statements either change inputs, outputs, or variables.

The language will be simpler to learn than some of the other PLC languages if you’ve worked with Basic or C.

Sequential Function Charts (SFC)

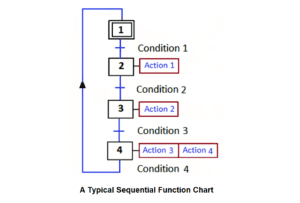

If you’ve worked with flow diagrams, you’ll feel right at home with this PLC computer language. If you have used flowcharts in the past, you will feel at ease using this PLC computer language. Sequential function charts allow you to achieve your goals by utilising steps and transitions. To accomplish your objectives, you employ steps and transformation in sequential function charts.

Instruction List (IL)

I will now demonstrate Instruction List, the fifth and last PLC programming language. Another text-based language is the Instruction List.

The Guidance List language is similar to Assembly Language. You will employ mnemonic codes like LD (Load), AND, OR, etc. when using this PLC programming language.

The Instruction List contains instructions, each of which is on a separate line with any comments you may want to include afterward.

How does a PLC operate

PLC triggers outputs based on pre-programmed parameters after processing data from input devices or connected sensors.

A PLC can perform a variety of tasks based on the inputs and outputs, including monitoring and recording run-time data like machine productivity or operating temperature, starting and stopping processes automatically, generating alarms in the event of a machine malfunction, and more. Almost any application can be accommodated using programmable logic controllers, which are robust and adaptable control solutions.

Want to get more information about What is plc program | The Core Systems please click on this google search link

Why chose The Core Systems for PLC programming training in Chandigarh?

The Core Systems is offering 6 weeks of Summer Training in PLC program training in Chandigarh for B.E., B.Tech, M.Tech, BCA, MCA, and Diploma students. The Core Systems places its graduates in the largest multinational corporations in India as well as abroad. For students receiving PLC ladder logic training From Core Systems, we offer 100% placement assistance.

Feel free to contact us for more details about PLC program training in Chandigarh | Mohali, and Punjab at our Chandigarh office

WhatsApp us

WhatsApp us