PLC Scada Training in Panchkula: Best Courses, Benefits & Career Opportunities

Introduction

When it comes to PLC Scada Training in Panchkula, TheCoreSystems has earned a solid reputation as one of the region’s most trusted institutes for industrial automation. With its state-of-the-art PLC Automation & SCADA lab, modern infrastructure, and industry-focused teaching methods, the institute has become a preferred destination for students and professionals across Chandigarh, Panchkula, and Mohali.

Unlike traditional training centers, TheCoreSystems emphasizes hands-on learning. Its advanced lab replicates real industrial environments, allowing learners to work directly on multi-brand PLC systems and live SCADA software. This practical approach ensures students don’t just memorize concepts but gain the skills required to solve real-world automation challenges.

The demand for skilled automation engineers is rapidly rising in India and abroad. Industries such as manufacturing, energy, oil & gas, automobiles, and process control now depend on PLC and SCADA systems to achieve maximum efficiency, safety, and cost-effectiveness.

For students and professionals in Haryana, enrolling in a recognized program like TheCoreSystems’ PLC Scada course in Panchkula can be a career-defining step. Whether you are a fresh graduate aiming to enter the job market or a professional planning to upgrade your technical expertise, this course provides the perfect platform to build a strong foundation in industrial automation and secure high-paying opportunities.

What is PLC (Programmable Logic Controller)?

A PLC is the “brain” of an industrial system—a rugged digital computer designed to automate processes such as:

- Controlling machines on factory assembly lines.

- Monitoring sensors and actuators.

- Running logic-based programs to improve efficiency.

Key Benefits of PLCs in Industries

- Reliability – Operates smoothly in extreme conditions (heat, dust, vibration).

- Flexibility – Easily programmable for different applications.

- Error Reduction – Reduces manual mistakes in production.

- Real-Time Control – Processes data instantly for accurate decisions.

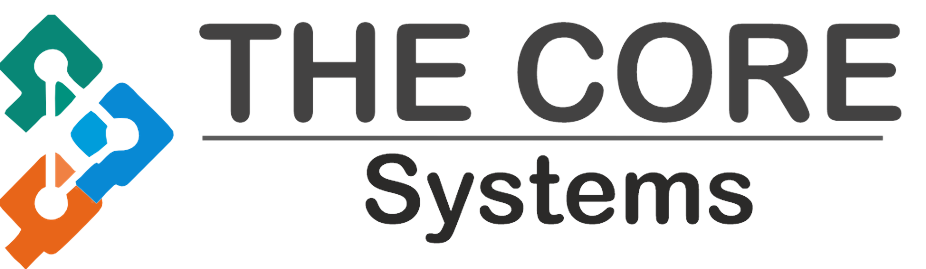

What is SCADA (Supervisory Control and Data Acquisition)?

While PLCs manage machine-level control, SCADA systems oversee and monitor entire plants and industrial networks.

Think of PLCs as the brain controlling machines, and SCADA as the central nervous system supervising everything on a larger scale.

A SCADA system combines hardware and software to collect real-time data from field devices, process it, and present it in a user-friendly interface for operators and engineers.

Key Features of SCADA Systems

- Visualization & Dashboards – Real-time monitoring of processes.

- Remote Access & Control – Operate systems from anywhere securely.

- Data Logging & Reporting – Maintain historical records for compliance & predictive maintenance.

- Alarm Management – Instant alerts for system failures or safety hazards.

- Integration – Works seamlessly with PLCs, HMIs, and industrial protocols.

- Scalability – Can expand from a single plant to multiple sites.

Applications of SCADA

- Power Generation & Distribution

- Oil & Gas Pipelines & Refineries

- Manufacturing Plants

- Water & Wastewater Treatment

- Food & Beverage Industry

PLCs handle control logic, while SCADA provides monitoring & optimization. Together, they form the backbone of Industry 4.0 and smart factories.

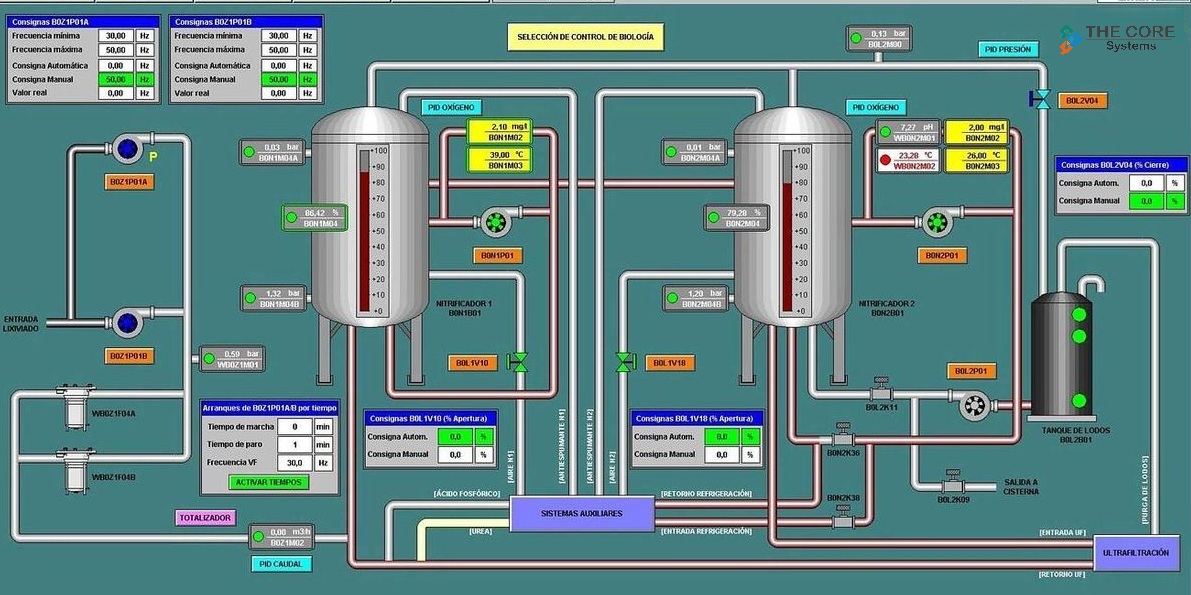

HMI Training (Human Machine Interface)

An HMI bridges operators and machines through dashboards, touchscreens, and computer interfaces.

What You’ll Learn

- Designing user-friendly HMI screens.

- Creating alarm systems & performance monitoring tools.

- Hands-on training with Siemens WinCC, Allen Bradley PanelView, Schneider HMI software.

- Integrating HMI with PLC & SCADA systems.

Career Benefits

- High demand for HMI Developers & Automation Engineers.

- Opens opportunities in smart factory & Industry 4.0 projects.

- Boosts employability when combined with PLC & SCADA skills.

VFD Training (Variable Frequency Drives)

A VFD controls motor speed and torque, making machines energy-efficient and reliable.

Key Concepts Covered

- Basics of AC motors & drives.

- Motor speed control & energy optimization.

- Communication with PLC, SCADA & HMI.

- Troubleshooting & diagnostics.

VFD training reduces energy costs, extends machine life, and increases global job opportunities.

Industrial Communication Protocols

Modern automation relies on industrial networking protocols for connectivity.

What You’ll Learn

- Modbus (RTU & TCP/IP) – Widely used for PLC-to-device communication.

- Profibus – High-speed process automation networking.

- Ethernet/IP & Profinet – Essential for Industry 4.0 & IIoT.

Why it matters: These protocols enable centralized monitoring, seamless integration, and faster troubleshooting.

Why PLC and SCADA Skills Are Essential

Automation is now a necessity. With the rise of IoT, robotics, and AI, industries worldwide are adopting Industry 4.0 technologies.

Professionals skilled in PLC & SCADA are in high demand across:

- Manufacturing

- Power Plants

- Oil & Gas

- Automobiles

- Food Processing

- Water Treatment

This makes PLC Scada Training in Panchkula a valuable investment for your future.

The Growing Scope of Automation in Panchkula & Haryana

Haryana hosts numerous industries from automobiles to FMCG. Panchkula, as part of the Chandigarh–Mohali–Panchkula tri-city, is becoming a hub for industrial automation training and placements.

Why Panchkula is Ideal for PLC Training

- Proximity to Chandigarh & Mohali ? better job opportunities.

- Growing industrial hub ? rising automation demand.

- Affordable education compared to metro cities.

TheCoreSystems – Best PLC Scada Training Institute in Panchkula

TheCoreSystems is a leading institute for automation training, with one of the most advanced PLC Automation & SCADA labs in the region.

- Features of TheCoreSystems’ Training Lab

- Advanced PLC Hardware Training – Siemens, Allen Bradley, Mitsubishi, Schneider.

- Hands-On SCADA Training – Wonderware, WinCC, InduSoft.

- Smart Factory Simulation – Robotics & IIoT applications.

- Industry-Oriented Curriculum – Designed with automation experts.

- Career Support – Placement assistance & industry certifications.

Who Should Join?

- Engineering Students – EE, EEE, ECE, Mechanical, Instrumentation.

- Working Professionals – Seeking promotions in automation.

- Entrepreneurs – Looking to upgrade their factories.

Career Opportunities After Training

- PLC Programmer

- Automation Engineer

- Control System Engineer

- SCADA Developer

- Instrumentation Engineer

- Salary Trends in India

-

Job Role Average Salary (INR/year) PLC Programmer 3.5 – 6.5 LPA Automation Engineer 4 – 8 LPA SCADA Developer 5 – 10 LPA Senior Automation Engineer 10 – 20 LPA - (Source: Naukri & Glassdoor India)

How to Choose the Right PLC Course Near Me

- Accredited & recognized institute.

- Access to real PLCs & SCADA software.

- Strong placement record.

- Balanced fees & duration.

FAQs – PLC Scada Training in Panchkula

- Q1. What is the course duration?

Ans :- 6 months depending on level. - Q2. Is PLC training suitable for freshers?

Ans :-Yes, beginners can start from scratch. - Q3. What are the fees?

Ans :-20,000 – 60,000 Rupee depending on the program. - Q4. Does TheCoreSystems provide placement?

Ans :-Yes, with industry tie-ups in India & abroad. - Q5. Can I work abroad after training?

Ans :-Yes, PLC & SCADA engineers are in demand worldwide. - Q6. Does the course cover HMI, VFD, and protocols?

Ans :-Yes, including HMI, VFD, Modbus, Profibus, Ethernet/IP.

Conclusion

- The future belongs to automation and Industry 4.0. If you’re in Panchkula or nearby areas, enrolling in TheCoreSystems’ PLC Scada Training will give you the skills, certification, and confidence to succeed.

- Whether you’re a student, a working professional, or an entrepreneur, this training can open doors to exciting, high-paying, and future-proof careers in automation.

WhatsApp us

WhatsApp us